Understanding the Downpipe B58

What Is a Downpipe B58?

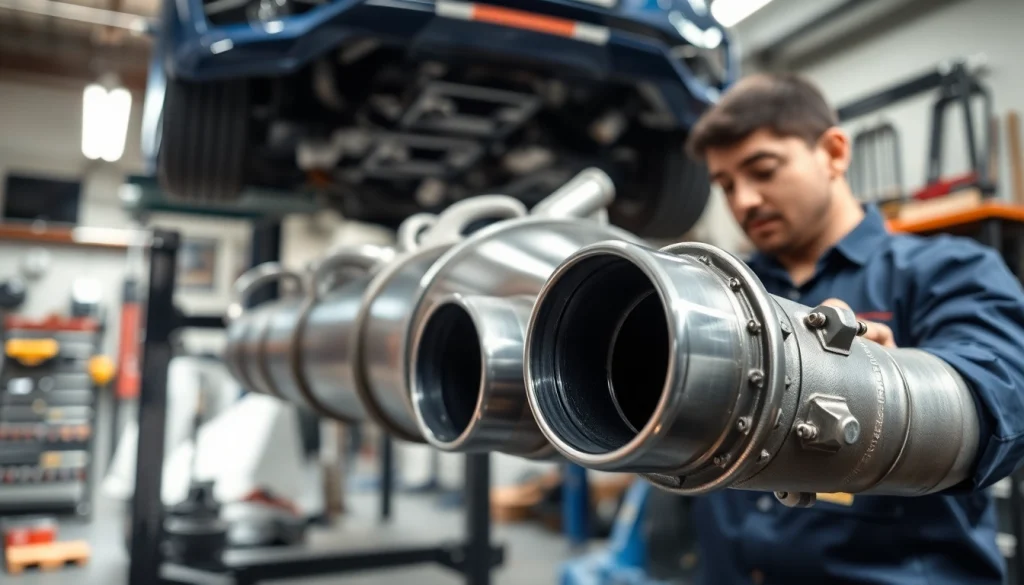

The downpipe b58 is an aftermarket component designed to optimize the exhaust flow from the turbocharger in vehicles powered by the B58 engine, commonly found in several BMW models. This modification is essential for performance enthusiasts looking to improve their vehicle’s horsepower and overall engine efficiency. The downpipe serves as a transition piece, connecting the turbocharger to the rest of the exhaust system, and is crucial for reducing back pressure, enhancing turbo spool, and improving throttle response.

Importance of the Downpipe in Performance Cars

A well-designed downpipe plays a pivotal role in the performance of a turbocharged vehicle. It allows exhaust gases to exit more freely from the engine, which is critical for maximizing power output. When the exhaust flow is impeded, it can lead to decreased performance, increased turbo lag, and higher exhaust gas temperatures. Therefore, upgrading to a performance downpipe such as the downpipe b58 can significantly impact not just how quickly the vehicle accelerates but also how efficient it operates at higher RPMs.

Key Features of Downpipe B58 Upgrades

- Material Quality: Premium options often use 304 stainless steel, which offers excellent resistance to corrosion and high temperatures.

- Design and Flow: Many aftermarket downpipes are designed with smooth bends and larger diameters to optimize flow, minimizing turbulence.

- Compatibility: The downpipe b58 is typically engineered to be compatible with stock exhaust systems, allowing for easier installation without the need for extensive modifications.

- Weight Reduction: Upgrading to a high-performance downpipe often reduces weight compared to factory components, which can improve overall performance.

Benefits of Upgrading Your Downpipe B58

Enhanced Performance Metrics

One of the most compelling reasons to upgrade to the downpipe b58 is the enhanced performance metrics it can provide. Users report significant increases in horsepower and torque, with some brands claiming gains upwards of 20-30 horsepower depending on the tune and other modifications. This performance boost is primarily due to the increased exhaust flow, which allows the turbo to operate more efficiently. Moreover, better exhaust flow contributes to quicker throttle response, making the vehicle feel much more dynamic on the road.

Improved Sound Quality

Another major benefit of upgrading your downpipe is the change in sound it brings to the vehicle. Aftermarket downpipes, especially catless variants, typically produce a deeper, more aggressive exhaust note compared to the restrictive factory units. Enthusiasts often enjoy the enhanced auditory experience, including turbo spool sounds and a more pronounced growl during acceleration. It’s important to note that while catless options can offer spectacular sound, they may not be legal in all jurisdictions due to emissions regulations.

Durability and Construction Materials

Upgrading to a high-quality downpipe b58 typically means investing in components made from durable materials that can withstand higher temperatures and resist corrosion. Stainless steel is often the material of choice due to its combination of strength, longevity, and resistance to heat. Unlike stock parts, many aftermarket downpipes are designed to handle increased exhaust temperatures generated by tuned engines, thereby ensuring reliability over an extended period.

Installation Insights for Downpipe B58

Preparation and Tools Needed

Before embarking on the installation of the downpipe b58, it’s essential to gather all necessary tools and materials. Common tools include:

- Socket wrench set

- Torque wrench

- Jack and jack stands

- Exhaust hangers removal tool

- Safety glasses and gloves

Additionally, having a high-temperature exhaust sealant on hand may also prove beneficial for perfecting connections and preventing leaks after installation.

Step-by-Step Installation Guide

Installing the downpipe b58 can vary depending on the specific vehicle and the type of downpipe chosen, but here’s a general guide to help you through the process:

- Preparation: Ensure the vehicle is parked on a flat surface and the engine is cool. Disconnect the battery to avoid any electrical shocks.

- Lift the Vehicle: Use a jack and jack stands to elevate the vehicle securely. Make sure it is stable before crawling underneath.

- Remove the Exhaust: Depending on the design, you may need to remove or loosen the factory downpipe. This process often involves detaching the exhaust hangers and unbolting the downpipe from the turbocharger.

- Install the New Downpipe: Position the new downpipe b58 into place. Start by securing it to the turbo and then attaching it to the rest of the exhaust system. Make sure to tighten all bolts to the manufacturer’s specifications.

- Reconnect Everything: Reattach any hangers and ensure all connections are tight. Reconnect the vehicle’s battery.

- Test the Vehicle: Start the engine and listen for any unusual noises or leaks. It’s advisable to let the vehicle idle for a few moments while checking for leaks before taking it for a test drive.

Common Installation Challenges

Installing a downpipe can present several challenges. Some of the typical hurdles include:

- Tight Spaces: Accessing the downpipe in cramped engine bays can make removal and installation challenging.

- Rusty Bolts: Factory bolts can corrode over time, making them difficult to remove. Consider using penetrating oil to loosen stubborn bolts.

- Exhaust Leaks: Ensuring proper sealing at the connections is essential to avoid exhaust leaks, which can lead to performance issues and undesirable noises.

Having a buddy to assist with the installation can streamline the process and make overcoming these challenges easier.

Choosing the Right Downpipe B58

Factors to Consider When Selecting

When choosing an aftermarket downpipe b58, several factors should be considered:

- Intentions: Are you looking for outright performance, or do you want a balance between power gains and daily drivability?

- Legal Compliance: Be mindful of local emissions regulations; some downpipe options may not be street legal if they remove catalytic converters.

- Budget: Performance parts can vary significantly in price. Ensure that your choice aligns with your budget while still delivering the desired performance.

- Installation Difficulty: If you plan on installing it yourself, consider how complicated the installation process is and if you have the necessary skills.

Catted vs. Catless Downpipes

A crucial decision to make when upgrading your exhaust system is whether to opt for a catted or catless downpipe. Catted downpipes maintain a catalytic converter, which can help reduce harmful emissions. This option is generally more compliant with emission laws, but it may offer slightly less performance compared to catless models. On the other hand, catless downpipes often provide the greatest performance gains due to unrestricted flow, but they can be illegal for street use in some areas due to increased emissions.

Evaluating Compatibility with Your Vehicle

Not all downpipes b58 are created equal; compatibility is key. Ensure you choose a downpipe that is specifically designed for your vehicle model and year. Check manufacturer specifications and seek out reviews from other users to guarantee a proper fit and to verify if any additional modifications might be necessary during installation.

Maintaining Your Downpipe B58 for Longevity

Best Practices for Maintenance

Keeping your downpipe b58 in good condition is essential for ensuring continued performance. Regular inspections can help catch potential issues before they become significant problems. Here are some best practices:

- Inspect connections and seals regularly for signs of exhaust leaks.

- Clean the exterior of the downpipe periodically to prevent rust and corrosion.

- Consider using a high-temperature sealant at the joints to maintain airtight connections.

Signs of Wear and Tear

Be vigilant for indicators that your downpipe may need attention. Some common signs include:

- Unusual noises coming from the exhaust system, which may indicate leaks.

- Reduced engine performance, with noticeable decreases in horsepower or increased turbo lag.

- Visible rust or corrosion, especially in stainless steel components.

Upgrades and Modifications for Optimal Performance

As automotive technology progresses, consider whether additional upgrades can further enhance your vehicle’s performance alongside the downpipe b58. Fitting an upgraded intercooler, optimizing your vehicle’s tune, or even upgrading other exhaust components can create a more synergistic performance package. These modifications can contribute to improved throttle response, enhanced power delivery, and better overall driving experience.